We are Manufacturer, Supplier of Polytetrafluroethylene (PTFE), Glass Filled PTFE, Bronze filled PTFE, Carbon Graphite filled PTFE, Carbon / Coke filled PTFE, Graphite Filled PTFE, Packings Bellows, Bearings, Protective Linings, Piston Rings, Ring Gaskets, PTFE machined parts, Valve Seats, Step Gaskets, Full Face Gaskets, Metal Insert Molding, Bush, Bellow, Tubings, O rings, U seal, Washers and our setup is situated at M.I.D.C., Ahmednagar, Maharashtra, India.

PTFE washers are sealing components commonly used in various industries due to their excellent chemical resistance and low friction properties.

PTFE washers used as spacers or seals between two mating surfaces. They are often used in applications where a reliable and durable sealing solution is required, such as automotive, aerospace, electrical, and chemical industries.

PTFE is highly resistant to a wide range of chemicals, acids, solvents, and corrosive substances, making it suitable for use in harsh environments.

PTFE has an extremely low coefficient of friction, which reduces wear and tear and allows for smooth operation even under high loads.

PTFE can withstand a wide range of temperatures, from cryogenic temperatures up to high temperatures of around 260°C (500°F) without losing its physical properties.

PTFE has a non-stick surface, which prevents substances from adhering to the washer, making it easy to clean and maintain.

PTFE is an excellent electrical insulator, providing insulation and preventing the flow of electric current.

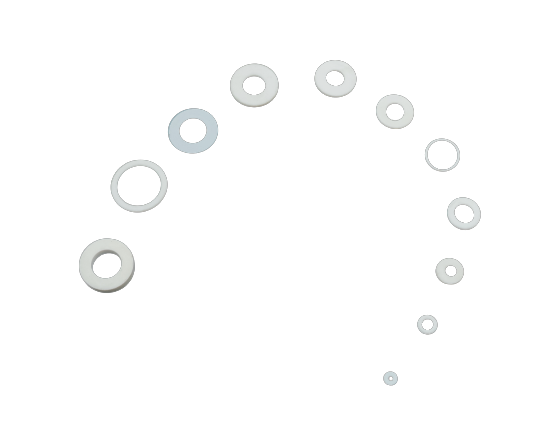

PTFE washers are available in various sizes, thicknesses, and shapes to suit different applications. They can be custom manufactured to meet specific requirements.